EDS applications

- Air conditioning

- Washing machine

- Electric Vehicle

- Steel rolling mills

- Pulp and paper mill

- Power supply fan

- Food processor

The structure of EDS

- Electric motor

- Mechanical load

- Power modulator

- Power supply

- Sensing circuit

- Control circuit

Types of electric motors

- DC motor:

- Separately excited

- Shunt

- Series

- Compound (long/short)

- Permanent magnet

- AC motor:

- Induction (Squirrel Cage, Wound Rotor, linear)

- Synchronous (wound, permanent magnet)

- Special motors:

- Brushless DC (less maintenance)

- Stepper (for robotics and control)

- Switched reluctance (space application - rotor light and less inertia)

Types of power modulators

- DC-DC Choppers:

- step-down (buck)

- Step-up (boost)

- Step-up & step-down (buck-boost)

- AC-DC Rectifiers:

- diode rectifier

- half-controlled rectifier

- fully-controlled rectifier

- Transformer with tap-changer + diode rectifier

- Diode rectifier + DC-DC chopper

- DC-AC Inverters:

- Voltage source inverter (VSI)

- Current source inverter (CSI)

- AC-AC converter:

- AC voltage regulator (fixed $f$ & V $\rightarrow$ fixed $f$ & variable V)

- Cycloconverter (fixed $f$ & V $\rightarrow$ variable $f$ & V)

Types of power supplies

- 1PH & 3PH 50Hz/60Hz 240/415V

- High power drive - 33kV, 6.6kV, 11kV

- Air craft 400Hz

- Electric traction (i.e. electric trains) - 1PH 6.25kV, 12.5kV, 25kV, 50kV

- DC power supply:

- Solar power

- Batteries

Advantages of electric drives

- No mechanical parts (no gears)

- Four quadrant operation

- No pollution (sound, emission)

- High efficiency

- Wide range of torque, speed, and power: Scalable (computer fan10W, mixer/grinder 100W, AC kW, industrial drives 100kW, locomotive MW)

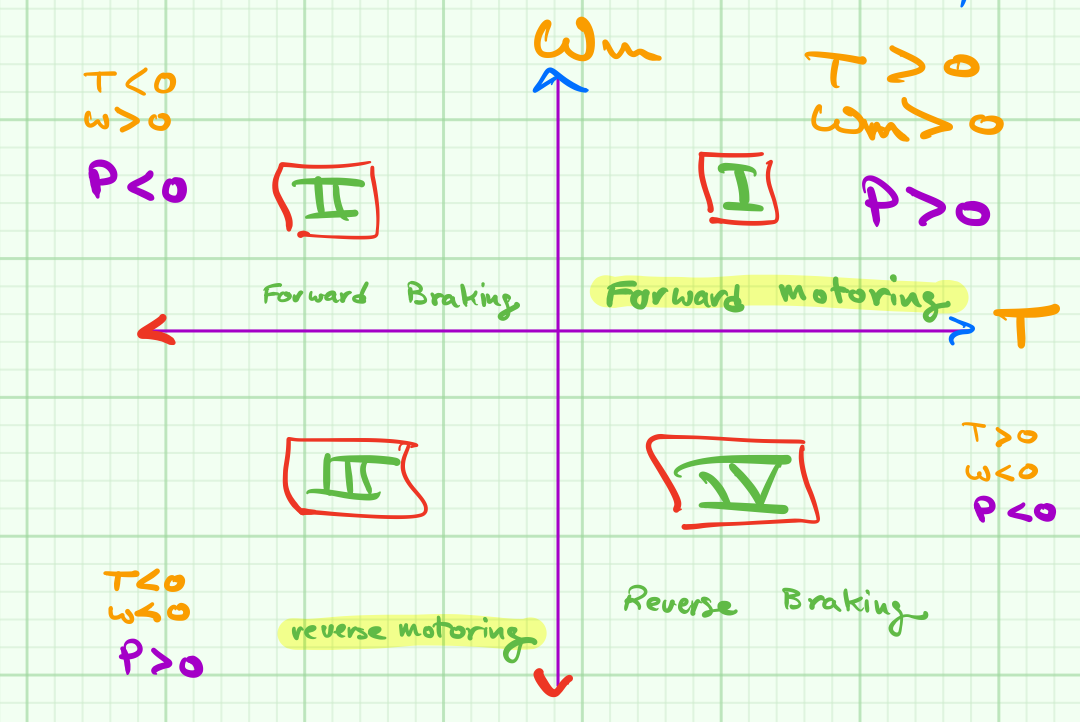

Four quadrant operation

$P=T \cdot \omega_m$

- if $P > 0$ power flow from PS to M

-

if $P < 0$ power flow from M to PS

Quadrant operation:

I : $T \gt 0$ & $\omega_m \gt 0$ $\longleftrightarrow$ forward motoring

II : $ T \lt 0 $ & $\omega_m \gt 0$ $\longleftrightarrow$ forward breaking

III: $T \lt 0$ & $\omega_m \lt 0$ $\longleftrightarrow$ reverse motoring

IV: $T \gt 0$ & $\omega_m \lt 0$ $\longleftrightarrow$ reverse breaking

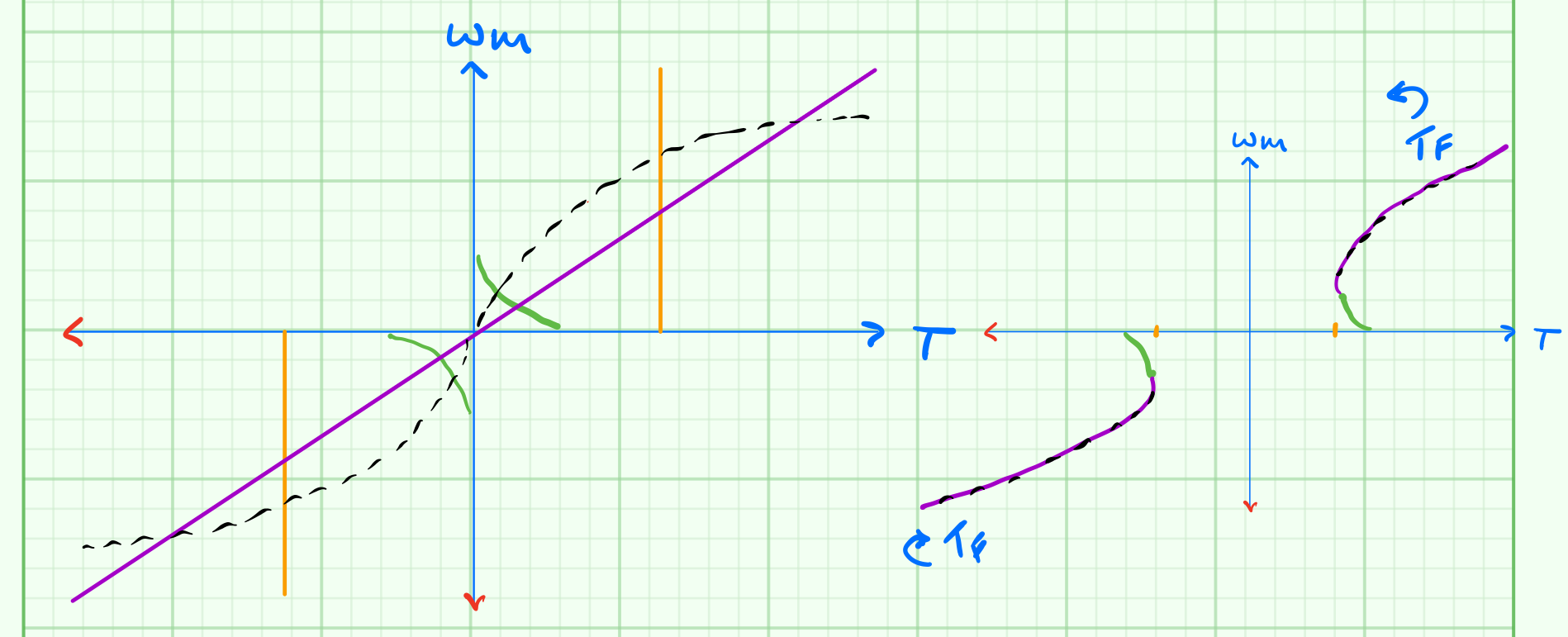

Load torque

$$\begin{equation} T_L = T_F + T_L^*\end{equation}$$

where $ T_L^*$ is the physical load torque and $T_F$ is the motor friction torque.

what are the components of load torque ?

The friction torque \eqref{TF} is composed of a number of motor related frictions. Some are constant, some are short lived, and others related to speed.

$$\begin{equation}T_F = T_S + T_C + T_V + T_W\label{TF}\end{equation}$$

- Static friction ($T_S$) - exists in static to low speed condition

- Coulomb friction ($T_C$) - independent of speed

- Viscous friction ($T_V$) - linearly proportional to speed

- Windage friction ($T_W$) - proportional to the square of speed ($\omega^2$)